‘Electrical equipment, including conductors, shall be provided with mechanical protection against electromechanical stresses of fault currents as necessary to prevent injury or damage to persons, livestock or property.’

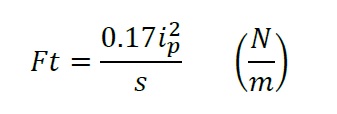

(The IET, 2011, 131.5 p17). The electromagnetic force generated during a short circuit fault is based on Amperes Law. Its magnitude is dependent on the short circuit current and the distance between the conductors with large currents and conductors at close spacings yielding the highest resultant force.

For single core cables in both trefoil and single flat spaced formation, the need to cleat cables in the event of a short circuit is obvious and widely accepted by system designers. Unrestrained or improperly restrained cables will move violently and with impact, potentially causing damage to nearby circuits, plant or people. The industry acceptance of fitting correctly specified cleating systems for single core cables is often not transferred to multicore cable installations. The reluctance to cleat multicore cables is commonly a result of the assumption that as the cores are fully encapsulated by the cable its inherent strength is sufficient to withstand the short circuit force of the conductors. This assumption is a vast over simplification. A proper assessment of multicore cables with regards to short circuit force withstand, should consider the following factors:

Short circuit current – The potential peak fault current can vary from system to system, the higher the current the higher the force. Regardless of the strength of the cable being used, if the peak fault current is high enough the conductors will break through the cable.

Spacing of conductors – In order to establish the short circuit force the spacing of conductors must be established. For multicore cables this is determined by the construction of the cable and the conductor spacing can often be found on cable data sheets.

Type of cable –The cable layers surrounding the conductors for multicore cables do offer a degree of restraint to the forces between the cores. The level of restraint offered varies with the construction configuration of the cable. For example a steel wire armoured cable will provide significantly more restraint than an unarmoured alternative. Cable manufacturers may be able to provide details of the strength of cable. Alternatively, Heinhold (1990) provides a methodology that allows engineers to calculate the approximate strength of cable based on construction type.

Short circuit testing of multicore cable is not within the scope of the international cable cleat standard, IEC 61914, and thus there isn’t a large library of data on short circuit testing of multicore cables. Ellis has experience of testing multicore cables and have seen instances where the conductors have pierced through the cable (Fig. 1) and also where it has been restrained within the cable. Even in instances where the conductors have been restrained there has been significant cable movement. Fig. 1 – Short circuit test showing conductors piercing through multicore cable. For full video click here.

It is Ellis’ viewpoint that, generally, not enough publicised information is present to compensate for the additional conductor restraint provided by multicore cable in the selection of cleat systems. Ellis’ calculations and cleat spacing recommendations for multicore cable assume the same logic as single core cables in trefoil. This may seem a cautious approach to many however it is important to note that cleats are safety critical items and to alter specifications based on assumptions is bad practice. Customers may wish to operate outside this recommendation and Ellis can understand the reasons behind this approach. Ellis, would however urge that a proper assessment is carried out before altering cleat recommendations. Ellis carry out a regular schedule of short-circuit tests. If you are planning a project and would like certainty regarding the cable fixings for your installation (whether single or multicore cables are included in the design) Ellis would be happy to conduct a short circuit test, on your behalf, within our regular programme of work. References:

The International Electrotechnical Commission, 2015. IEC 61914:2015: Cable cleats for electrical installations. Geneva: The International Electrotechnical Commission.

The Institute of Engineering Technology and British Standards Institute, 2015. BS 7671:2008: Requirements for Electrical Installations – IET Wiring Regulations. London: The Institute of Engineering Technology in agreement with BSI.

Heinhold. L. (1990) Power Cables and their Application (Part 1) 3rd edn. Munich: Siemens

Harry Taylor – Mechanical Engineer (05/08/19)

Ellis Patents Ltd.

High Street,

Rillington, Malton,

North Yorkshire YO17 8LA

United Kingdom

Company registration number: 10293983

Registered in England and Wales

VAT number: GB125424145

© Ellis Patents 2025 | Terms and Conditions | Cookie Policy | Sitemap

Website by Askew/Brook